More durable…better electrical and optical properties…smart.

First used tens of thousands of years ago for tiles, bricks and pottery, ceramic materials were recognized for their strength properties and ability to withstand chemical erosion and extreme temperatures.

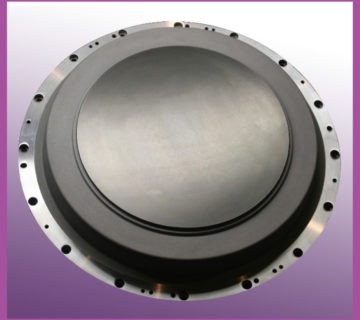

Today, as metallic oxides, nitrides and carbides or elements such as silicon and carbon, ceramics have a vital role in many industries. Shaped into planar or cylindrical targets, ceramics are widely applied to materials such as thin film coatings via sputtering, a form of physical vapor deposition (PVD).

Developments in material science have improved the performance of thin films applied with ceramic targets for better durability, higher density materials and the availability of alloys customized to specific applications. These advancements have expanded the uses of ceramic sputtering targets.

Optical coatings

Ceramic sputtering targets are crucial in producing optical coatings for lenses, mirrors, sensors and other optical devices. Known for its excellent refractive index, titanium dioxide (TiO2) sputtering targets are commonly used to make anti-reflective and high-reflectivity coatings while silicon dioxide (SiO2) is frequently applied in optical films for transparency and durability, making them ideal for producing protective and decorative coatings.

Architectural and automotive glass coatings

Sputtered ceramic coatings are used on architectural and automotive glass to create focused properties, including thermal insulation and conductivity.

Imaging (Optoelectronics)

Optoelectronics are electronic devices that source, detect and control light, both visible light and invisible forms of radiation, including gamma rays, X-rays, ultraviolet light and infrared light. Optoelectronic devices can be divided into two different types: light detecting devices, including photodiodes, phototransistors and photoresistors and light generating devices such as light emitting diodes (LEDs), cathode ray tubes (CRTs) and laser diodes. Because of their optical transparency, thermal stability, electrical insulation and mechanical strength, ceramic materials are essential in producing optoelectronics. Materials used in optoelectronics are similar to those of semi-conductor materials and include aluminum oxide (Al₂O₃) and aluminum nitride (AIN). Other common ceramic materials used in optoelectronics include barium titanate (BaTiO₃) and vanadium oxides, which are used for their specific electro-optic properties, nonlinear optical behavior and infrared detection capabilities.

Medical coatings

When it comes to health, there is no room for compromise. Ceramic coatings on medical implants and surgical tools serve to improve biocompatibility, reduce friction, boost durability and corrosion resistance, provide antimicrobial properties and improve the visibility and handling of devices. These coatings can be made from silicones or silicon dioxide (silica), applied using processes such as plasma-enhanced chemical vapor deposition (PECVD) and are designed to resist adhesion, create necessary surface properties and deliver drugs. Common applications include implants, vascular stents and surgical instruments.

Hard coatings

Ceramic materials like aluminum oxide (Al₂O₃), titanium nitride (TiN), titanium carbide (TiC), titanium oxide (TiO₂) silicon carbide (SiC) and silicon dioxide (SiO2) leverage the inherent hardness, chemical stability, and high-temperature resistance of ceramics to significantly extend the life of tools and parts in industries like mechanical engineering, aerospace, tool coatings and automotive. These coatings can be engineered with various microstructures and compositions, including single-layer, multi-layer, and composite designs, to optimize their performance for specific tribological applications, reducing friction, wear and corrosion.

Coatings for electronics

In semiconductors, integrated circuits (ICs), materials such as silicon dioxide (SiO2) are commonly sputtered to produce insulating layers that enhance device performance and reliability.

In addition, alumina substrates, which primarily consist of aluminum oxide (Al2O3) often with small additions of other elements, modify properties such as thermal conductivity and mechanical strength. Silicon carbide (SiC) substrates exhibit excellent thermal conductivity for high-powered electronics.

Coatings for solar applications

Materials such as aluminum-doped zinc oxide (AZO) and tin oxide (TiO2) are used to create thin film layers that boost light absorption and electrical conductivity in highly efficient solar panels.

Display screens

In OLED and LCD displays, indium gallium zinc oxide (IGZO) sputtering targets are often used to apply insulating layers and transparent conductive films.

Coatings for renewable energy

The renewable energy sector leverages ceramic sputtering targets to improve the efficiency of devices like solar panels and batteries

and cutting-edge touch interfaces. Ceramic sputtering targets contribute to the development of protective coatings in thin film batteries to ensure stability and longevity. Some smart ceramic coatings have characteristics like temperature or light sensitivity, enabling them to adjust automatically in response to changes in the external environment.

A pure advantage

While the selection of a ceramic sputtering target depends on film property and application requirements, with their versatility, excellent physical properties and ability to deposit high-quality thin films, ceramic rotating and planar sputtering targets find applications in a wide range of industries and technologies. Working with high-quality materials from a trusted supplier like Process Materials ensures optimal performance and long-term reliability.