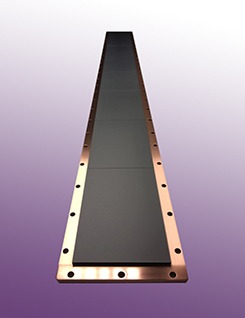

PROCESS MATERIALS

A SPUTTERING TARGET SUPPLIER

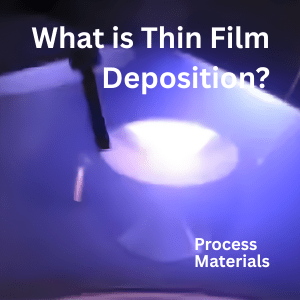

TECHNOLOGIES

Process Materials ensures the integrity of our sputtering targets because of our advanced, controlled process technology. From sintering to thermal spraying to vacuum, powder and casting metallurgy, we meet our customers’ PVD requirements on every order, whether large or small.

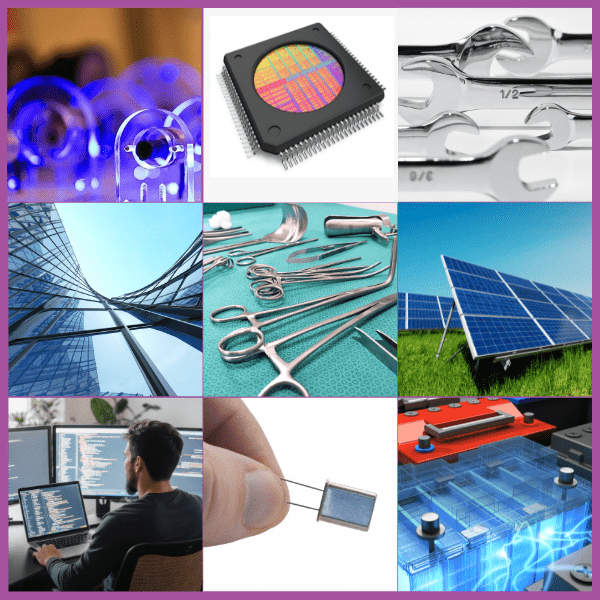

APPLICATIONS

Process Materials serves the Architectural and Automotive glass producers, Optics, Hardware and Tooling Coaters, Medical Device, Photovoltaics, Flat Panel and Touch Panel Display industries plus Semiconductor customers worldwide from R&D to Production operations.

GUARANTEED WORKMANSHIP

The people at Process Materials understand the company’s future rests on instilling ethical values and a positive culture.

We assign every order for sputtering targets with proven techniques, flexible capabilities, and the finest fabrication, measuring, and testing equipment. Analysis of materials includes glow discharge mass spectrometer (GDMS) testing for trace elements, atomic absorption testing for major contaminates within the metal, and c-scan testing for bond integrity.

We guarantee the quality of the material, machining, and bonding.