If you’re working in semiconductors, solar, optics, or advanced coatings, chances are you rely on thin film deposition to deliver performance and reliability. Among the many deposition methods, sputtering has become a go-to process because it offers precise control, scalability, and compatibility with a wide range of materials.

This article (linked below) explains how sputtering works—turning a solid target into a thin film that coats your substrate with the exact properties you need. From thickness uniformity to electrical performance, every variable in sputtering ties back to the quality of the materials and the control of the process.

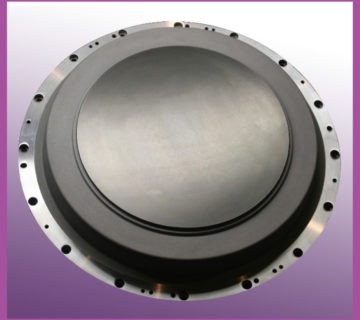

At Process Materials, we specialize in supplying the high-purity sputtering targets and consumables that make these results possible. The consistency of your coatings depends on the integrity of your materials. That’s where our expertise and product quality give you an edge—helping you minimize downtime, reduce defects, and achieve predictable outcomes target after target.

👉 Read the full article here too see how sputtering works and why your choice of materials makes all the difference.

https://www.semicore.com/news/70-thin-film-deposition-sputtering

Contact us with your target specifications and we can provide you with pricing information.

No comment