SI SPUTTER TARGET

Several steps are taken to make sure external product specification are on target and meet customer expectations before the final product is delivered to the customer.

PRODUCTION METHODOLOGY

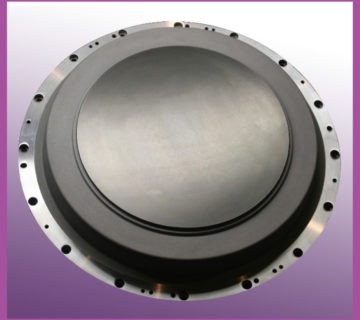

The target material is thermally sprayed and receives a surface finish. An adhesion-promoting layer is present on the stainless steel backing tube (SS 304). After quality control, the targets are wrapped in protective paper or foam, packed with silica gel in PVC bags and fixed in wooden crates for shipping.

ANALYTICAL METHODS

ICP/AAS analyzes chemical composition

ICP analyzes impurity levels

O/N element analyzer measures O/N levels

Balance with water vessel measures density

Metallographic analyzes microscopy

SURFACE FINISH AND APPEARANCE AT SHIPMENT

No cracks visible to the naked eye

Visible inclusions and/or hole (<0.1mm = acceptable; 0.1-0.5 = 5 in a 10mm annular ring; >0.5mm = unacceptable)

In order to meet external product specification, we assign every order for sputtering targets with proven techniques, flexible capabilities, and the finest fabrication, measuring, and testing equipment. Analysis of materials includes glow discharge mass spectrometer (GDMS) testing for trace elements, atomic absorption testing for major contaminates within the metal, and c-scan testing for bond integrity.

We guarantee the quality of the material, machining, and bonding.